1. Manual Powder Coating Machine Price Overview and Components

A Manual Powder Coating Machine typically includes a handheld electrostatic spray gun, powder hopper, airflow regulator, grounding system, and compact booth. These machines prioritize simplicity and affordability, making them ideal for small workshops. Prices vary based on build quality, recovery efficiency, and optional features like HEPA filters or adjustable voltage settings.

2. Applications of Manual Powder Coating Machines

Used in automotive repair shops, furniture restoration, metal fabrication, and DIY projects. Manual powder coating machines apply durable finishes to car parts, tools, bicycle frames, and home decor items. They are suitable for low to medium production volumes.

3. Factors Affecting Manual Powder Coating Machine Price

Prices range from 1,000to10,000, depending on:

Size: Compact booths (4x4 ft) cost 1,000–3,000; larger units (8x6 ft) reach 5,000–10,000.

Material: Stainless steel frames add 20–30% to costs compared to aluminum.

Features: Advanced airflow controls or IoT-enabled monitors increase prices by 15–25%.

4. Proper Usage of Manual Powder Coating Machines

Clean surfaces via sandblasting or chemical pre-treatment. Set voltage to 30–80 kV and airflow to 8–20 psi. Maintain a 6–10-inch spray distance for uniform coverage. Cure parts at 350–400°F for 10–20 minutes. Clean nozzles and filters after each use.

5. How to Choose a Manual Powder Coating Machine

Production Needs: For <50 parts/day, opt for basic models (1,000–3,000).

Powder Compatibility: Ensure the machine supports epoxy, polyester, or metallic powders.

Safety Certifications: Look for CE, UL, or OSHA compliance.

Warranty: Prioritize suppliers offering 1–3-year warranties.

6. Safety Precautions for Manual Powder Coating Machines

Wear NIOSH-approved respirators (N95+) and anti-static gloves.

Ground all equipment to prevent electrostatic discharge.

Operate in well-ventilated areas to avoid inhaling particles.

Store powders in fireproof containers away from heat sources.

7. Cost-Efficiency of Manual Powder Coating Machines

Manual systems reduce upfront costs by 60–70% compared to automated alternatives. While labor-intensive, they offer ROI within 6–12 months for small businesses through low maintenance and material savings (70–85% powder recovery).

8. FAQs About Manual Powder Coating Machine Price

Q: What is the average manual powder coating machine price?

A: Basic models cost 1,000–3,000; premium units with high recovery rates reach 8,000–10,000.

Q: Can manual machines handle large parts?

A: Yes—booths up to 8x6 ft accommodate components like car doors or furniture frames.

Q: Are used manual powder coating machines cost-effective?

A: Yes—refurbished units (500–2,500) suit budget-conscious buyers but require thorough inspection.

Q: How to reduce powder waste in manual systems?

A: Use cyclone recovery systems (80–90% efficiency) and reusable filters.

Q: What maintenance affects manual powder coating machine price long-term?

A: Annual filter replacements (50–200) and nozzle upgrades (30–100) minimize downtime.

This guide breaks down manual powder coating machine price variables, helping buyers balance affordability, safety, and performance for small-scale coating projects.

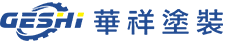

Disclaimer: Enhance your coating process with advanced electrostatic powder coating machines, precision powder coating spray guns, comprehensive powder coating systems, and efficient powder coating lines from Hangzhou Huaxiang Coating Equipment Co., Ltd. Designed for reliability and high-quality finishes, our solutions meet all your industrial powder coating machine needs. Contact us at sale3@cncolourspray.com