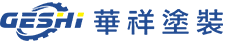

1. Introduction to Professional Powder Coating Machines

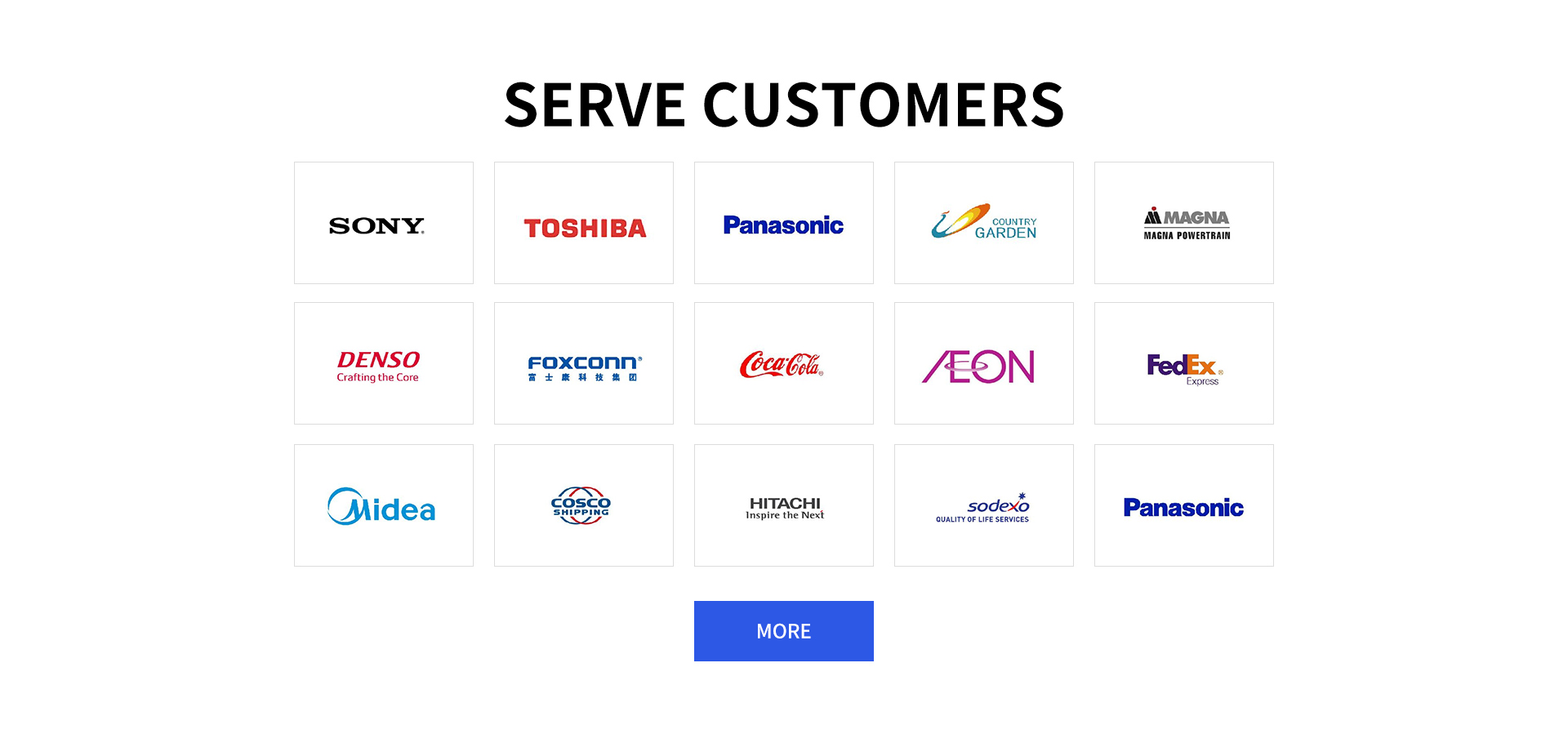

A Professional Powder Coating Machine is an industrial-grade system designed to apply dry powder coatings to metal surfaces via electrostatic charging and thermal curing. Core components include a spray gun, electrostatic generator, curing oven, conveyor belt, and powder recovery unit. These machines ensure uniform, durable finishes while reducing waste, making them ideal for high-volume production and industries prioritizing efficiency and environmental compliance.

2. Applications of Professional Powder Coating Machines

Widely used in automotive, aerospace, construction, and appliance industries, these machines coat components like engine parts, bicycle frames, architectural fixtures, and household appliances. They excel in applications requiring corrosion resistance, aesthetic appeal, and adherence to strict industry standards.

3. Pricing of Professional Powder Coating Machines

Prices range from 15,000forsemi−automaticsystemstoover250,000 for fully automated lines. Mid-tier models (50,000–150,000) balance advanced features like programmable controls and energy-efficient curing ovens. Costs vary based on automation, size, and powder recovery capabilities.

4. Proper Use of Professional Powder Coating Machines

Prepare surfaces by removing oils and debris. Adjust electrostatic voltage (60–100 kV) and spray distance for optimal adhesion. Cure coated items at 300–450°F for 10–30 minutes. Regularly clean spray nozzles, replace filters, and calibrate equipment to maintain consistent coating quality.

5. How to Choose a Professional Powder Coating Machine

Evaluate production volume, part size, and material type. Automated systems suit mass production, while manual options offer flexibility for custom projects. Prioritize energy-efficient designs, OSHA-compliant safety features, and compatibility with multiple powder formulations.

6. Safety Precautions for Professional Powder Coating Machines

Operators must wear PPE (respirators, gloves, goggles) to avoid inhaling particles. Ensure proper grounding to prevent electrostatic discharge. Maintain ventilation to reduce dust accumulation and fire risks. Regularly inspect electrical systems and curing oven temperature controls.

7. Design Efficiency of Professional Powder Coating Machines

Modern machines feature modular designs for scalability, energy-saving curing ovens, and closed-loop powder recovery systems that recycle up to 95% of overspray. Advanced electrostatic technology ensures precise application, reducing material waste and supporting sustainable manufacturing practices.

8. FAQs About Professional Powder Coating Machines

Q: What is the machine’s lifespan?

A: With routine maintenance, they last 10–20 years, ideal for high-volume industrial coating.

Q: Can they coat plastic substrates?

A: Yes, using specialized powders for pre-treated automotive plastics.

Q: How to reduce energy consumption?

A: Opt for infrared curing ovens and optimize thermal cycle settings.

Q: What causes powder clumping?

A: Humidity exposure—store powders in dry conditions and ensure proper electrostatic charging.

Q: Are these machines eco-friendly?

A: Zero-VOC emissions and efficient powder reuse align with green manufacturing standards.

Disclaimer: Enhance your coating process with advanced electrostatic powder coating machines, precision powder coating spray guns, comprehensive powder coating systems, and efficient powder coating lines from Hangzhou Huaxiang Coating Equipment Co., Ltd. Designed for reliability and high-quality finishes, our solutions meet all your industrial powder coating machine needs. Contact us at sale3@cncolourspray.com